Product structural features:

The machine bed is made of high quality cast iron, the shape of the rectangular column structure, good rigidity, stable performance.

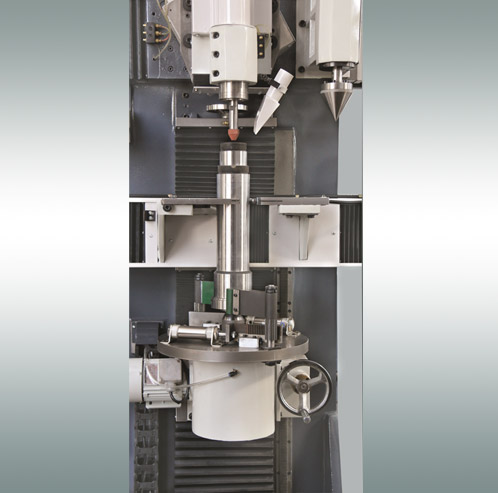

The machine tool is composed of the bed, the grinding head device, the clamping device, the tailstock device, the workpiece rotating device, the dust suction device, the cooling device, the machine control cabinet and the operation box.

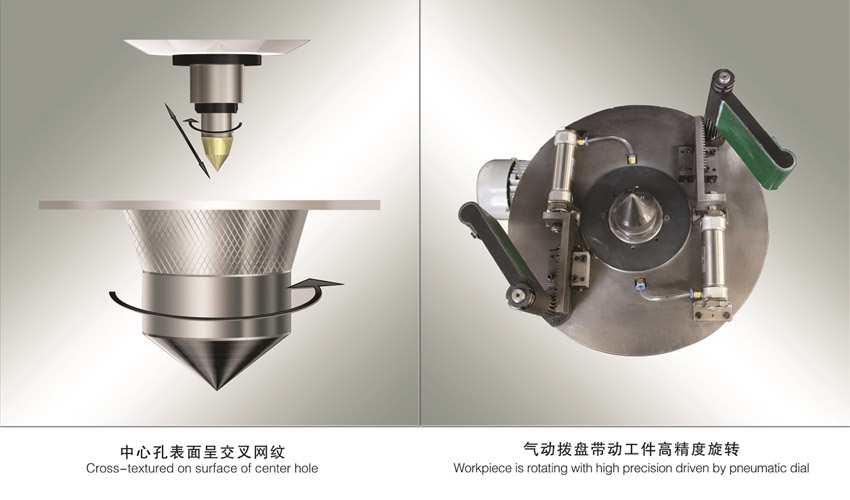

The grinding head device is lateral moves along the guide rail of the bed to realize the positioning of the workpiece and the grinding centering. Grinding shaft reciprocating motion along the central hole of the generatrix to achieve oscillating grinding.

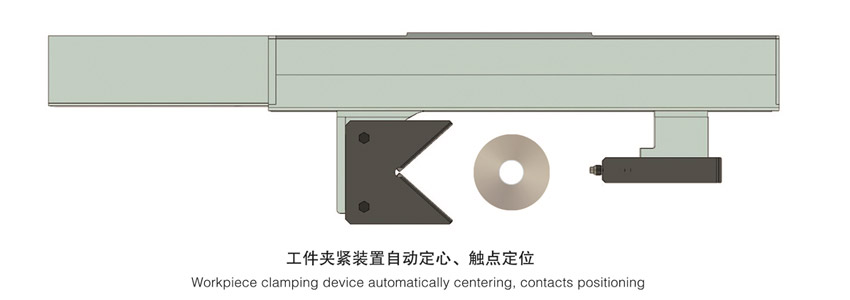

The grinding shaft seat drives the grinding shaft to move vertically along the guide rail, to achieve the grinding positioning and feed by the left and right movement. Servo to intensify the workpiece, positioning accuracy. Pneumatic driving, drive the workpiece high precision rotation, can realize the automatic loading and unloading.

Control mode:PLS + positioning control module。